Posted on June 27th, 2017

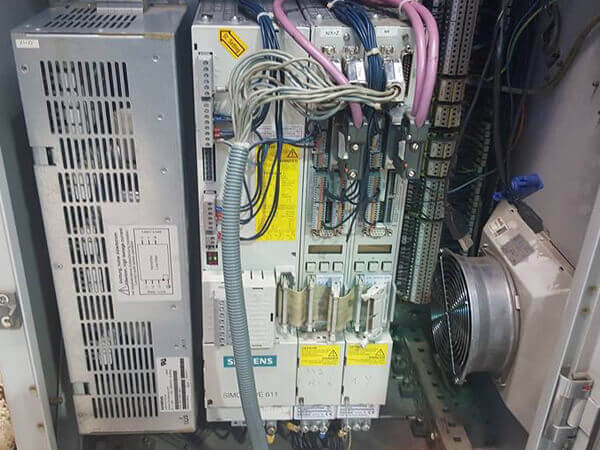

We were recently contacted by a new customer who found us by recommendation from a company we support on a regular basis. This customer based on the south coast had returned to their machine, an Emag VSC 400 Duo with Sinumerik 840D and 611D drives and suffered huge issues. On returning power to the machine, a large bang was heard and machine power was lost resulting in an alarm 120202 waiting for connection to NC PLC with a flashing control panel. No sign of life from NCU and first bank of drives.

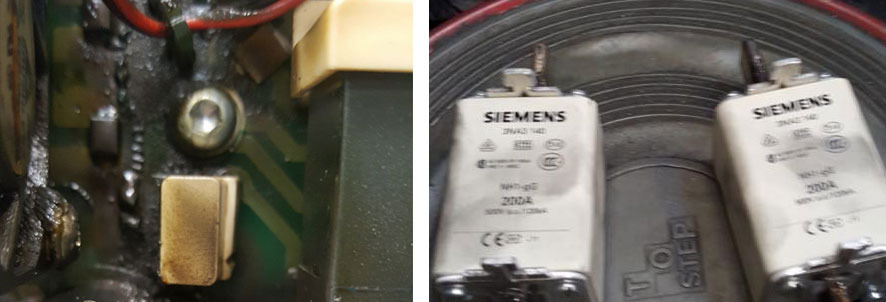

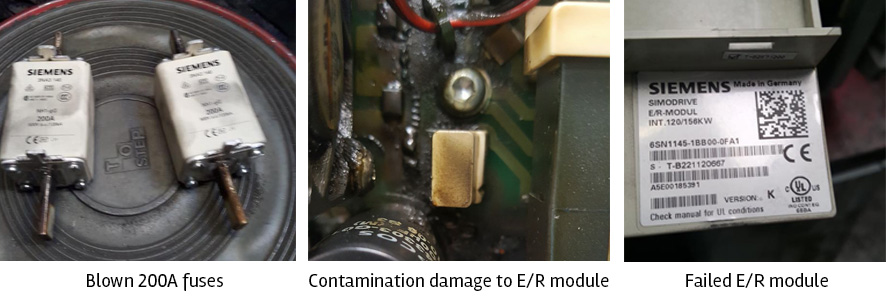

On attending site, we immediately discovered that 3 main 200A fast burn fuses had blown, this indicated something on the power supply side had failed / gone short. Each drive was separated and individually health checked along with all of the motors and cables, these were all given a clean bill of health. We then discovered that the main 120 / 156 KW E/R module had blown, on inspection 2 of the 3 phases were at dead short which was a clear indication of why the main 200A fuses had blown. The electrical cabinet housing the drives was found to be heavily contaminated with carbon dust (a by-product of our customer’s production process) which we believe to be the root cause of the failure. When the machine was powered down and all of the fans stopped, the air born dust settled on the main board of E/R module, when it was powered back up, this dust created a dead short causing the catastrophic failure of the module.

After a thorough clean and inspection, a new E/R module was sourced and fitted, the machine was then safely powered back up 1 drive at a time to safeguard the existing hardware and to ensure that there were no other undetected issues. Once the machine was fully powered back up, it was referenced and all positions and tooling data reset and checked. New backups (NC, PLC and ghost images) were then made of the machine and given to the customer, the machine was then returned to production.

We advised the customer about the electrical cabinet housekeeping, vacuum cabinet on a regular basis, keep doors closed and filters clean to prevent ingress of air born contaminants. Good housekeeping will help prevent future costly failures like this and preserve the machine lifecycle.

At Control CNC Services Ltd, we offer a cost effective CNC machine prevention maintenance service to help keep your business up and running.